Roubo Build: One Stout Bench Top

Everything I’ve done for the past 6 weeks has built to this bench top completion. It isn’t easy milling up 8 ft long sub assemblies that weigh over 50 lbs apiece. However, the wisdom gained was worth the effort invested, and the rest of the Roubo build to should go more quickly.

I can’t believe the stability of the Roubo bench top. There’s zero flex, even with my 190 lb frame down bearing directly over the center. It don’t think it would have a problem with a Buick parked on top. At nearly 200 lbs and 4 1/2 inch thick, it shouldn’t have any problems with the modest amounts of abuse it will see over its lifetime. Overall, the build has gone smoothly, but it hasn’t been without its lessons.

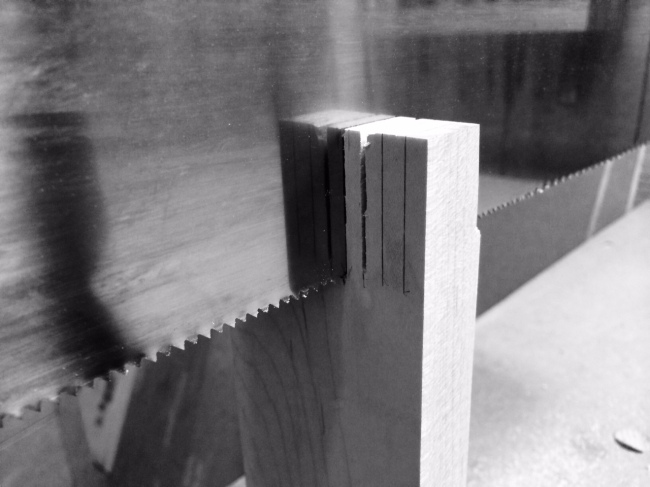

The biggest lesson I’ve learned is to take your time. I sped through the early stages and ended up with some small gaps in the sub assemblies. This is likely due to small amounts of snipe from the planer, which I didn’t initially notice. I don’t expect this to affect bench top durability, but it is a constant reminder of my impatience. The seams between the sub assemblies are virtually gap-less. I will mask the gaps with some epoxy, unless anyone can give me a better solution.

If you attempt a build like this take your time, plan, and don’t hesitate to ask for help. The legs are already in progress. I have already ripped, jointed, and stickered the boards. With any luck, I will have the blanks glued up by the end of the weekend. Stay tuned…

You can find links to my other Roubo Build posts here: Project Index