Drill and Driver Storage

Progress on the workshop feels slow. It’s probably because I have taken on too many projects at once. Fortunately, I crossed one project off the list last night. I wanted something that would keep my drills and drivers off the ground; something that would keep them within reach. I found plenty of inspiration on the Internet. This drill and driver storage unit is what I came up with.

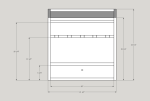

I can store all of my drills and drivers in one place. I store the chargers on top, and have a nice little drawer for all of my bits and accessories. The unit mounts to the wall using a french cleat. There is a small power strip secured below the top using adhesive Velcro. The power cord for the strip passes through the side, while the power cables for the chargers pass through the top.

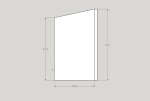

I made the entire unit from 3/4″ birch plywood, and I spent less than $50 for the entire build. That includes plywood, drawer slide, drawer pull, and power strip. I found everything at my local Home Depot. If I hadn’t been tied up with other projects, this little drill and driver storage unit could have been built in a couple of hours. Below, I will include the Sketchup and a couple of drawings. Feel free to customize this for your own tools.

Stay safe and have fun.