The Mortise Jig

The Idea

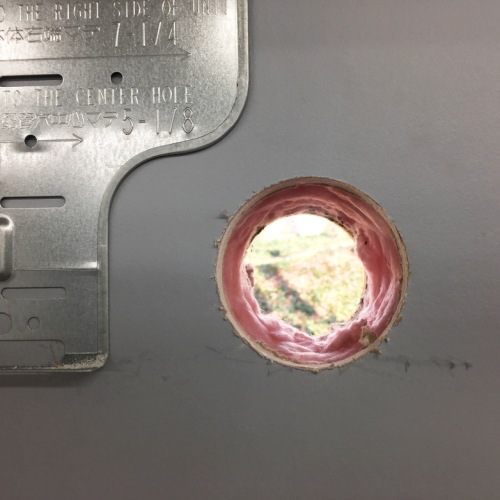

Above everything, I want to create beautiful and unique furniture. The furniture which draws my attention has a common theme: mortise and tenon joinery. Ideally, I would create mortises with a dedicated hollow-chisel mortiser. Unfortunately, I don’t have the space or funds available for such a wonderful tool. As a result, I have determined that my best course of action is to use the plunge router for mortising.

To improve speed and accuracy, I followed Jeff Miller’s advice and built mortise jig. I followed Jeff’s design fairly closely, but made some minor improvements to the original plan. For example, I added a t-track and adjustable stop blocks for better repeat-ability.

The Design

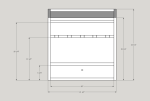

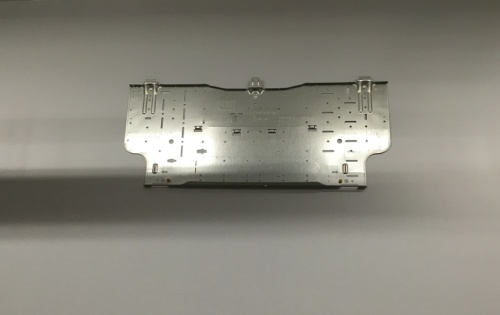

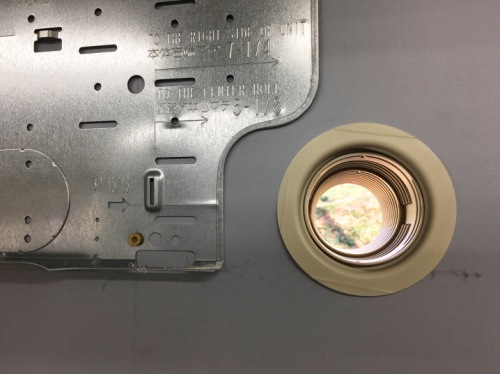

The jig is simple in design and easy to make. It consists of a platform, a track, and a pair of hold-down clamps. I milled an auxiliary fence for my router at the same time I milled the parts for the track. This ensures a perfect fit to guide the router.

A 8/4 white oak board with too many knots for furniture sat on my lumber rack. It had just enough straight grain to mill up the parts for the jig. I laminated two pieces to make the platform. Then, I cut a dado for the t-track. I built the guide by resawing another strip of oak. The resawed pieces produced three 3/4-inch strips: two for the guide and one for the auxiliary fence.

I glued the guide pieces together. However, I did not permanently attach the guide to the base. It attaches using 3/8-inch bolts that are also used to secure the hold-down clamps. This allows me to replace the track if it wears out over time.

The Results

I eased the sharp edges with a block plane, and applied paste wax to the fence. So far, the jig works extremely well. I plan to use it on a few projects that I have coming up. Stay tuned.